Pulleys and levers. Remember them? Yes, those concepts you learned in high school physics are the heart of the NS Design patented tuning system found on all the NS Design headless instruments. In particular, US Patent 6,528,710.

Ned has been perfecting tuning systems for guitars and stringed instruments going all the way back to the beginning, US Patent 4,192,213 for his legendary headless bass. The screw based tuning mechanism was key to the overall function of the instrument. In this tuner, the ball end of the string is held in a jaw, which is threaded to accept a screw that pulls the string taut. In this kind of system, the free end of the string is held in a clamp which requires a tool to operate or the use of strings with a ball at both ends.

The common tuning systems in use today create tension in the strings by wrapping the free ends around tuning posts fixed at the head end of the instrument neck, which posts are turned through a worm gear arrangement to create the required tension. This system, has stability problems because the worm gear drives needed to operate the tuning posts have backlash making precise tuning difficult, and also the strings can slacken around the posts after once being tightened, detuning the instrument. In looking for ways to improve the conventional system, Ned came up with the Gearless Guitar Tuner, US Patent 5,057,736, considered by many guitar players to be the ultimate headstock tuner.

Which brings us to today’s tech talk, the NS Design Patented “self clamping” tuning system. Simple in its design, using the time tested physics of levers, this headless tuning system provides extremely accurate tuning and quick, easy string changes without the need for wrenches or double ball strings.

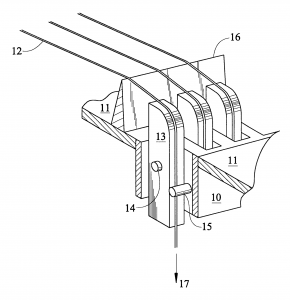

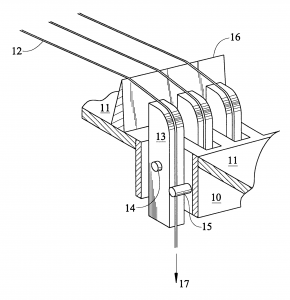

The tuner uses its own string tension, through lever action, to provide the clamping force necessary to hold the string securely. A tuning screw drives a second lever to increase or decrease the tension in the string.

The amount of pinch pressure applied to the string is determined by the ratio of the lever arms, in accordance with the elementary principles of mechanics. By appropriately setting the lever arm ratio, the amount of pinch pressure may be made sufficient to prevent string slippage, while at the same time not severing the string due to excess pressure. The relevant lever arms are 1) the distance from the contact between the string and the lever to the pivot pin and 2) the distance between the pinch pin and the pivot pin. The actual pinch force is influenced both by the lever arm ratio and the angle at which the pinch pin presses against the lever.

While a single lever can be used to properly multiply the string tension and provide the needed force to hold the string, in order to more easily, and more accurately tune the string, additional mechanical advantage to pinch the string is obtained by including a second lever.

If you look at the drawings, it becomes clear just how simple, yet effective this design is. First, the tension of the string itself pushes the lever arm toward the “headstock” to pinch the string against a pin, which holds the string in position. The more tension, or force toward the “head” of the instrument, the greater the force to hold the string against the pin. Now adding the second lever arm, and using a screw mechanism to move that lever arm, not only adds force to hold the string, but also causes the lever arm position to move, enabling one to tune the string. Also, the increased tension on the string increases the holding force proportionately, assuring a high degree of stability even at very high string tension.

Simple. Effective. Efficient. Innovative.

For more iNSight and information on a weekly basis, look for our Tech Tuesday and TBT – Throwback Thursday posts on the NS Facebook page: https://www.facebook.com/ThinkNS/